What is Blown Fiber Installation in FTTH: Infect FTTH cables are installed by pulling in sub-ducts and small ducts in the traditional way using cable pulling equipment, or by using air blowing methods. Blowing Fiber is a method where the fiber is guided through sub- or mini ducts or micro-ducts using a flow of air that evenly distributes the installation force along the entire length of the fiber.

➥Micro cable, 4-216 fibers, outdoor and indoor version. In FTTH network optical fiber cable required from 4 strands to 216 strands. Its depend upon the fiber design in FTTH and requirements of the customers. During traditional way of cable pulling 4-8-12 strands fiber can be damage. We know that air reduce the friction between optical fiber cable jacket and the inside wall of the duct or micro duct. So suitable and best method is blowing method.

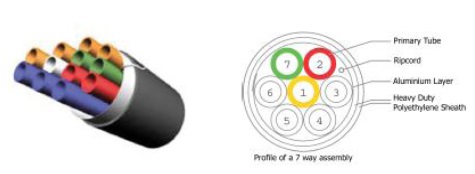

Small diameter low friction HDPE tubes provide the dedicated pathway for the optical fiber units. Micro ducts are provided for the installation into existing cable ducts, direct buried or inside buildings (internal). The tubes are available in a variety of sizes, combinations, 5/3.5, 7/5.5, 10/8, 12/10, 14/12 mm, etc.(outside/inside) diameters, loose or with protective layer system; and supplied on drums.

This fiber can be blown several kilometres along zig-zagging routes and even up and down buildings. Using the air has the effect that the propelling force exerted on the fiber unit is substantially the same throughout its length, and this force is less than the maximum force present in a conventional optical fiber cable that is being installed by pulling.

The blown fiber system consists of the following components

➥Micro ducts for installation in existing cable ducts.

➥Multi micro ducts for direct burial.

➥Accessories, duct branches and duct joints.

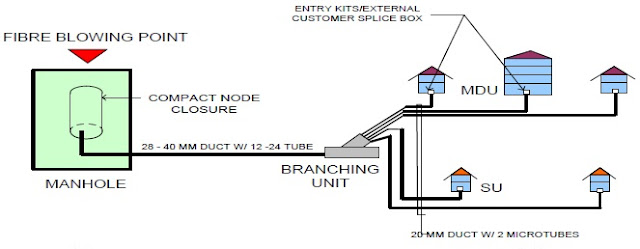

The blown fiber system is arranged in network.We are talking about blown fiber but how are the arranged in FTTH network. Two type of friction overcome during the traditional cable pulling- static friction and dynamic friction. Static friction exist between the contact surface and dynamic friction exist between the contact surface but in motion state. That's why we use lubricant whether the traditional cable pulling or is air blowing method.Now in below image we will see the blown fiber system is arranged in FTTH network.

Micro Cable used for Blown

The fibers used for blown fiber cables shall be Single-mode (SM), coated with two layers of acrylic that gives excellent protection to the fibers and also arrange fibers in bundles for easy identification. The cable construction has outer diameter of 1.0 to 8.5 mm depending on the number of fibers (4 – 216) & can easily be deployed in empty micro ducts.

The fibers used for blown fiber cables shall be Single-mode (SM), coated with two layers of acrylic that gives excellent protection to the fibers and also arrange fibers in bundles for easy identification. The cable construction has outer diameter of 1.0 to 8.5 mm depending on the number of fibers (4 – 216) & can easily be deployed in empty micro ducts.

Advantages of Micro Cable

Micro cable which used for blown in FTTH network is extremely slim and light cable, still with high fiber count. It is more flexible and small bending radius.It has very good installation properties.It has high crush resistance, 1kN.Sheath is easy to remove and Very easy to prepare mid-span access.According to climate changes it has excellent environmental performance. It is very suitable for both for outdoor and indoor applications.

Micro cable which used for blown in FTTH network is extremely slim and light cable, still with high fiber count. It is more flexible and small bending radius.It has very good installation properties.It has high crush resistance, 1kN.Sheath is easy to remove and Very easy to prepare mid-span access.According to climate changes it has excellent environmental performance. It is very suitable for both for outdoor and indoor applications.

Blown Tubes (Micro Ducts)

Micro ducts are available many sizes (1, 2, 4, 5, 7, 12, 19, 24 tubes, etc). The tubes have all been rigorously tested and enable the blown fiber units to be blown the optimum distance within the tube.

An integral part of Blown Fiber Solution is the tube connection and tube sealing products. A wide range of products are available which enable tubes to be connected together, sealed from water or gas ingress, or reduced from one tube size to another, sealing & end caps. This range of accessories is fully compatible with the Blown Fiber Units and Blown Fiber Tube.

|

| Blown Tubes |

Micro Tube Accessories for Blown Fiber Installation in FTTH

|

| Blown Tubes Accessories |

Compact Node Closure

A closure used in manholes where blown fiber cables are spliced (to traditional or blown fiber cables). It is supplied with 12 single circuit splice trays and sufficient components for installing one cable, enabling the breakout of up to 24 fibers (dual fiber circuits) to customer drop cables. Distribution cables are installed through fiber cable entry kit.

Branching Unit (Tube Distribution Center

Used for management and distribution of fibers to the customers. The unit provides in-line and diversion connections with the use of "Y" and "T" tube joints.

Entry Kit (External Customer Splice Box)

This is the Customer Lead-In Unit, installed at the customer outer wall for termination of incoming fibers. It may be of two parts mounted on either side of the wall connected by a length of tube (conduit). Comprises: blow fiber unit, customer lead in unit, connecting conduit & terminating box. Normally, called Fiber Termination Box (FTB).

Equipment & Tools

FTTH blowing tools & equipment consist mainly of a Compressor & Blowing Head and fiber guiding fittings & accessories (regulators, coilers, pan guides or supports, etc.).

The compressor provides clean dry air to the blowing head and the tubes, usually at a rate of 10 / 13 bars.The blowing head accommodates a number of fibres (2, 4, 8 etc.) to be blown into the micro-tubes at the same time.

0 Comments